Company history

Heinrich Koch, the founder of Sikoplast, was already a tinkerer and inventor at a young age. As a teenager, he completed an apprenticeship as a lathe operator at the company Mletzko & Walterscheid in Siegburg and thus acquired a sound knowledge of mechanical engineering.

Shortly after his apprenticeship, he set up his own business and, after buying a lathe in his parents' house, began to manufacture machine stands and basic frames for drilling machines and lathes. With a lot of ambition and diligence, he built up his business and expanded his product range to include plastic products.

In 1952, his company "Sieg-Kunststoffe" participated for the first time in the plastics trade fair in Düsseldorf, where he presented his innovative products. Heinrich Koch kept coming up with new ideas and received numerous patents for his inventions in the plastics processing industry.

He joined forces with Battenfeld, but the cooperation did not last long. So Heinrich Koch left again and laid the foundation for today's Sikoplast company in 1956.

When at the beginning of the seventies the oil crisis temporarily caused the raw material price of plastics to rise sharply, a new market for recycling plants also emerged.

Heinrich Koch saw this as the future for his company and from this time on developed plants and systems for the recycling of plastics. This development was consequently continued, even when other companies stopped it again. One building block of this success is the conical single-screw extruder. This often copied screw system is still today in modified form the heart of the SIKOPLAST recycling plants.

In 1986, the foundation stone of today's SIKOPLAST Recycling Technology was laid. Since then, SIKOPLAST's product range has been continuously expanded and extended. In addition to conventional recycling plants for the processing of production waste, today's product range includes washing plants and systems for the processing of post-consumer waste, as well as silos, conveyor belts, granulators and granulation systems.

Today's SIKOPLAST Recycling Technology laid the start of its new direction in 2021 with the move to the new sales and service office in Troisdorf.

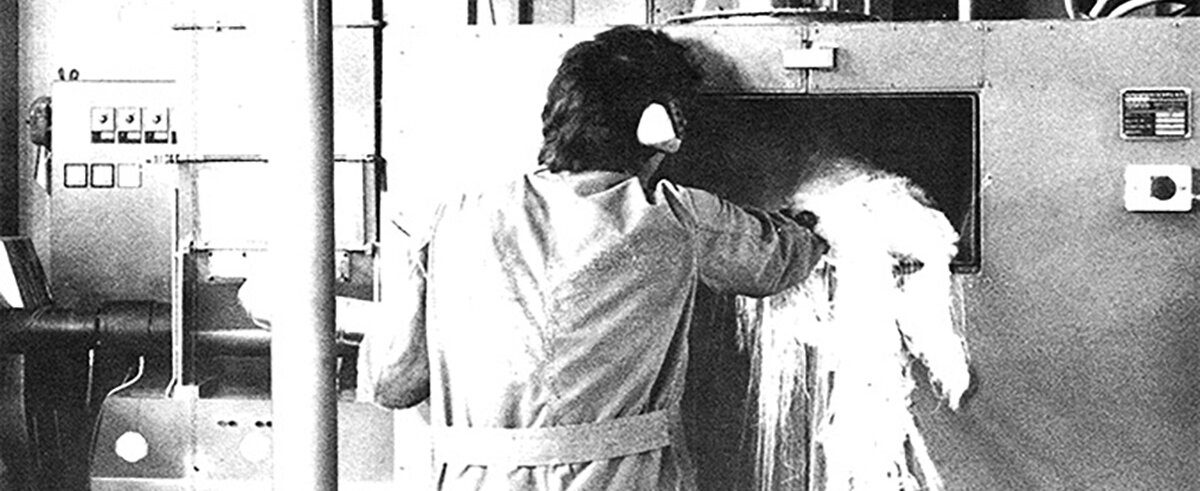

Production plant

Our employees play a critical role in the design and manufacture of our recycling machines. Each employee brings unique skills and expertise that enable us to build high-quality machines that meet our customers' needs.

Our team strives to constantly develop innovative solutions to meet the demands of the ever-evolving recycling industry. Close cooperation and a smooth exchange of information within the team allow us to continuously improve our products to meet the latest standards and requirements.

The employees at our production plant are proud to contribute to the protection of our environment and to reduce our ecological footprint. We greatly appreciate their commitment and passion for producing first-class recycling machines and will continue to invest in their development and training to ensure that we can continue to produce high-quality machines.