Pelletising systems

The pelletising systems presented below are available both individually to complete third-party systems and in conjunction with our complete pelletising lines. Depending on material and throughput, the following systems are used:

- Waterring pelletising systems type HAW

- Underwater pelletising systems type UWG

- Air-cooled pelletising systems type HG

How it works

- The homogenous melted plastic is fed through a circular holed nozzle.

- The melted plastic that exits the circular holed nozzle is cut off with a rotating blade head.

- Then the pellets are cooled using either air or water and transported off.

- In the subsequent cooling area or the centrifugal dryer, the pellets are cooled or dried to a temperature at which the form is stable.

- In order to achieve pellets that are of the same size, the material is passed over a screen vibration unit.

- In the last stage, the pellets are filled into big bags, octabins, containers or material sacks.

Characteristics of air cooled hot waste pelletising systems - type HG

Our recycling plants with air-cooled hot die face are the first choice when it comes to pelletising LD, LLD, MD and HD-PE thermoplastics in lower throughput ranges.

In addition to process reliability, the system is characterised by its compact construction and maintenance-friendly design.

Characteristics of water-ring pelletising systems - type HAW

The waterring pelletising systems of the HAW series are easy to operate systems. Their field of application is the pelletizing of PE, PP, PS, ABS and similar plastics.

The pelletising system is completely mounted on the process water tank and forms a compact unit. In addition to the pelletising head, the scope of supply includes the process water tank, a centrifuge and a heat exchanger. The pelletising systems of the HAW series can be easily connected to almost all existing extruders or their screen changers or melt pumps.

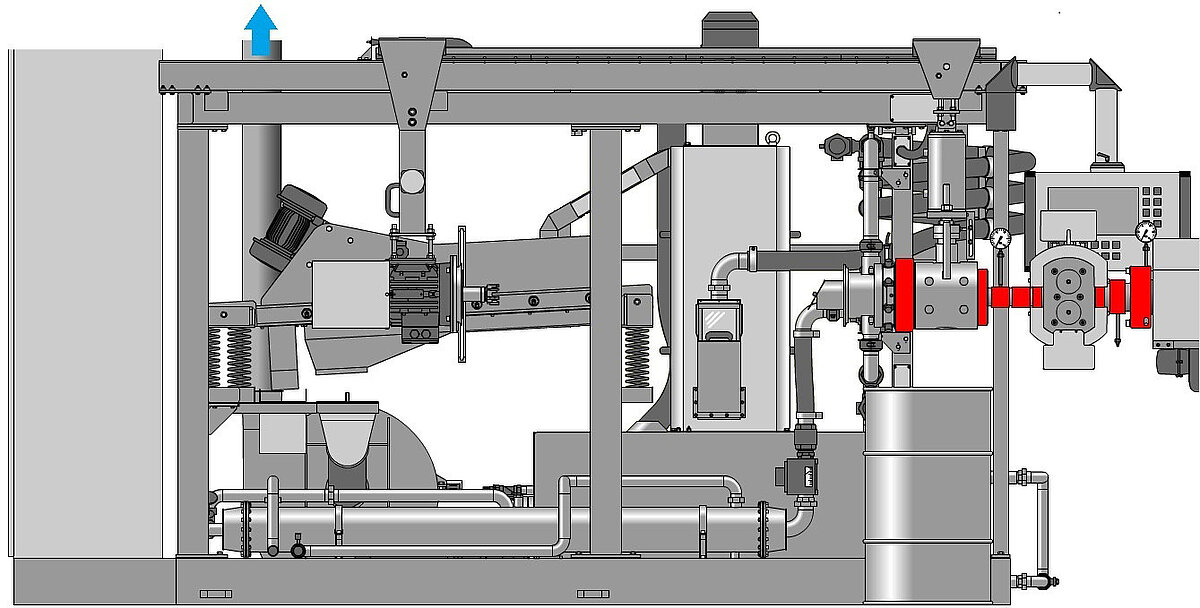

Characteristics of Underwater pelletising system - type UWG

The underwater pelletising system of the UWG series is characterised by its flexible field of application. It can be used to pelletise almost all plastic melts, even viscosities that can no longer be processed with normal strand pelletising or water ring pelletising systems.

The plastic melt exits through a perforated nozzle arranged in a circle and is cut off by blades rotating directly on the nozzle. In contrast to water ring pelletising, the entire cutting chamber of underwater pelletising is filled with water, i.e. the cut is made "under water". The pellets are cooled by the water and due to the high flow velocity are transported directly from the cutting chamber to the centrifuge. There the granules are separated from the water and dried. The process water flows back into the water tank, from where it is pumped back into the pelletising head after prior cooling.

An automatic start-up system ensures that melt and water come together at the same time during start-up, thus preventing the blades from smearing and the nozzle from freezing. In addition to the large processing window, the UWG is characterised by its small space requirement and its user-friendliness. Especially at higher throughput rates, the UWG has a clear advantage over strand or waterring pelletizing systems. In addition to PE, PP, ABS, PS, PA, PET, TPU etc. can also be pelletised in a reliable process.

Added to this is the processing of viscosity ranges that can no longer be processed on conventional systems. For a special application, for example, a PP Melt Blown material with an MFI of 1,100 (g/10 min, 230°C) is successfully granulated with the aid of a UWG. The UWG can easily be connected to almost all commercially available extruders or their screen changers or melt pumps.

Extruder systems offline

Our recycling extruders - optimised for the feeding of light, non-free-flowing feed materials.

To extruder systemsSikorex edge trim system

The SIKOREX series form the basis for an economic preparation - optimised for the return of roll material or for direct edge trim return.

To Sikorex edge trim systemHybrid edge trim system

The HYBRID system covers all requirements of a modern spunbond production - even on high-speed winders with speeds above 1,500 m/min a direct edge trim return is guaranteed.

To Hybrid edge trim systemWashing plants

Our washing system with friction washer and the patented wet separation stage with integrated pre-flotation enable above-average purity grades, even with heavily soiled feed material.

To washing plants