In-line recycling plants for thermo-plastic plastics | Hybrid

Due to its flexible task the HYBRID-System covers all requirements of a modern spunbond production regarding waste treatment. In addition to rolled goods (incl. master rolls), loose waste can also be returned, as can edge strips, which are sucked off directly by the rewinder. Even with high-speed winders with speeds of more than 1,500 m/min, direct edge trim return is guaranteed. Thus the available winding width can be used optimally and in many cases an increase of the usable winding width can be achieved. The material feed into the extruders has been designed in such a way that the production area is not contaminated and thus also allows the use in the hygienic or medical sector.

Full integration into the production process

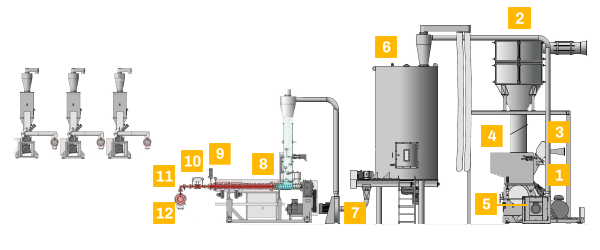

The granulator is ideally positioned in a separate room near the winder/rewinder. In addition to a roll infeed for feeding roll material, loose cut waste can be fed manually. The granulator is equipped with a cyclone for direct edge trim return. A silo is used for intermediate storage and enables edge trim extraction in connection with rewinders working in a batch process.

When developing the HYBRID systems, great importance was attached to the fact that they can be completely integrated into the production process. In master-slave mode, a once set percentage feedback rate is kept constant. This means that the HYBRID system automatically adjusts to changes in throughput on the production line. In combination with material and energy-saving preparation, high return rates can be achieved without any loss of quality.

How it works

- Pre-crushing, usually by a granulator.

- The pre-shredded feed material is transported into the extruder silo by a blower.

- An agitator integrated in the silo ensures a uniform feed of the extruder, regardless of the material. The extruder is then fed with the pre-shredded material.

- In the extruder, the heart of the plant, the material is finally gently melted under oxygen exclusion and thus without oxidation.

- It first passes into the screen changer arranged downstream and then into the pelletising head, where the melt is processed into pellets and then dried in a centrifuge.

- The granulate is transported by a blower into a big bag station, a silo or a container.

Areas of application

- Specially developed for the non-woven and PE/PP film industries

- Non-wovens(SMS) with high MFI values and 100% "melt blown" proportion can be processed with the highest process stability

- Direct return feed of production residue in the form of melted material to the production plant

- For the return of roller goods, edge trims and loose waste with infeed speeds of up to 1,500 m/min

- Existing plants can easily be retrofitted

Our supply range includes standard systems with material through-put performances from 30 kg/hour to around 250 kg/hour (per extruder)

Variable material feed: Manually by the plant operator, pneumatically via a feed pipe and fully-automated with a draw-in roller

Roller goods with a width of up to 4.2 m (depending on area weight) can be drawn into the system via the draw-in roller of the granulator

Direct feeding of the edge trims with speeds of up to 1,500 m/min. The winding of edge trims in a rewinder is eliminated

Direct feeding of the melted plastic into the production extruder. The intermediate pelletising stage is eliminated with no need for a replacement stage

The hybrid system is fully integrated into the production process. Once set, the return quota is maintained constantly. In the event of through-put changes to the production plant, the hybrid system is automatically continued

An integrated melt pump ensures a precisely defined return quota

An integrated screen changer serves to eliminate contamination in the melted material

The energy consumption is, when compared to OFF-LINE systems, half as expensive

The entire process is gentle on materials and energy. There is no precompaction of thermal pre-treatment This means that the material is not pre-stressed.

Extruder systems offline

Our recycling extruders - optimised for the feeding of light, non-free-flowing feed materials.

To extruder systemsSikorex edge trim system

The SIKOREX series form the basis for an economic preparation - optimised for the return of roll material or for direct edge trim return.

To Sikorex edge trim systemHybrid edge trim system

The HYBRID system covers all requirements of a modern spunbond production - even on high-speed winders with speeds above 1,500 m/min a direct edge trim return is guaranteed.

To Hybrid edge trim systemWashing plants

Our washing system with friction washer and the patented wet separation stage with integrated pre-flotation enable above-average purity grades, even with heavily soiled feed material.

To washing plants